New here but I have an itch to pursue better accuracy at 200y with my one CF gun and thinking it might be educational to shoot a few CBA benchrest matches this summer. Not to be competitive but to learn and if the bug bights.....

I have a bunch of moulds but my 30 cal list is short, an Ideal 31141. My bullets have been good enough to be very competitive in CLA (Metallic Silhouette Cowboy Lever Action) but there are times I wonder what went wrong when IMO I had a good break. Sadly, a 200y range is a 2 hour drive and winter in NH this year has limited outside activity. So here I am doing what I should NOT be doing, sitting inside, warm, on the computer.

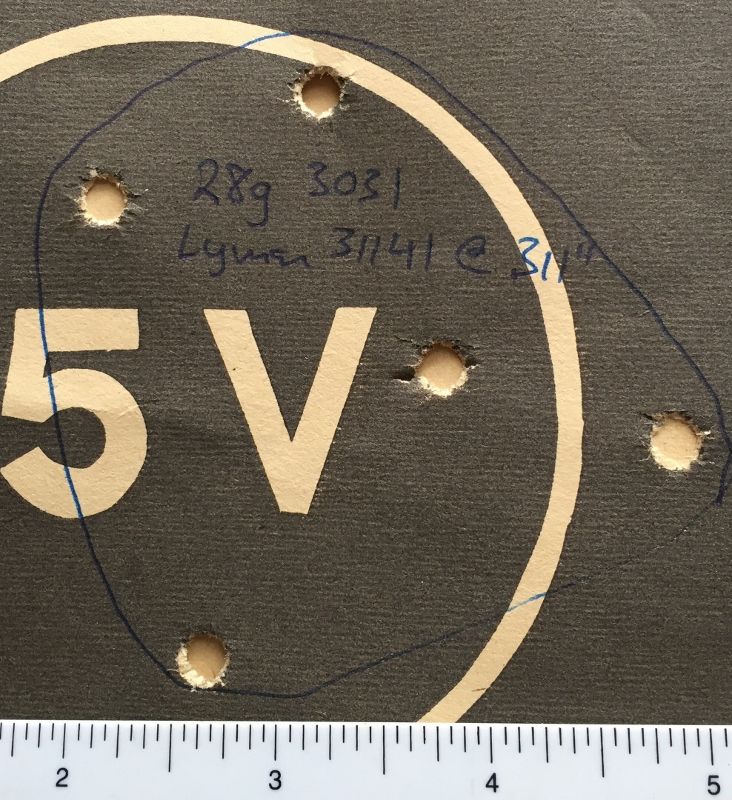

As I do research, there are so many variables that lay ahead, what do I focus on if I want to develop a better 200y hand loaded bullet for a CBA match? 31141 has a BC of .220. A low value and higher is better. Browse FleaBay and find other .311 mould such as a 311299 which has a BC of .377. The bullet can, I would assume, be single loaded to avoid magazine detonation, and would bore ride with correct LOA. Would this be the first best building block in the foundation of a cast bullet with higher accuracy potential? But, is this the right direction to take? Yet another mould? There are so many other variables to explore first with the .31141. What's first? I have read so much my head hurts. Here are a few.<>Manage alloy better, put 20 ingots and melt them to the IDENTICAL alloy, and then pour them to ensure I have one variable eliminated. Today I use ingots which I have created by collecting range lead to WW to whatever I find and now 300 ingots stashed away.<>Get a higher BC mould. Higher is better at 200y from a 30-30.<>Using the pencil method, use the hardest ingots I can collect from my stash and melt them to one alloy. I don't own a hardness tester...read enough on that.<>Sizing. I have sizers from .310 to .313. yet my current 300 load ready bullet inventory is all sized to .311 and GC. Bullet drops at .312 to .313 and is not round or perfectly aliened...and I have worked hard on that. I am told Lyman moulds are not perfect.<>Crimp. Taper, factory, or don't crimp at all. Too much crimp negatively impacts the driving bands. More crimp assures more consistent powder burn.<>Neck tension & turning...sorry, not going there for a 30-30.<>Case prep. That is easy. All the same headstamp, trimmed, flash hole deburred, weight sorted...I feel I have that in the bag on a RP case. Of course a few bags of Factory New...defeats my interest to be frugal but I understand penny wise, pound foolish.<>Powders...Unique has worked, I own it...seems like a slippery slope to start buying a pound of 5+ powders to experiment...laddering each...mix in the above variables...my head hurts....to truly change one variable at a time the testing would be beyond what I have time to accomplish.

I find a classic case of analysis paralysis and I spend more time thinking about it and less time doing it. What would the accuracy veterans work on first? Should the buy bight, a 30 cal bolt gun could take my efforts with the 30-30 to the next level next year.

JD in NH